To understand the advantages of quartz glass compound eye lens in laser application

Release time:

2024-03-02 16:48

Source:

In daily laser application, the light emitted by the light source will generally have an uneven phenomenon. If these light is used directly without processing, the maging of the light source will appear with different brightness. The flyeye lens is formed by a series of small unit lenses. By the application of the double-row flyeye lens array to the illumination system, high light energy utilization and large areas of uniform illumination can be obtained. The key to achieving uniform illumination is to improve its uniformity and illumination brightness.

Flyeye lenses can be widely used in display, projection, 3D printing, lithography lighting, cameras, mobile phones, projectors, security monitoring and other consumer electronics and astronomy, biology, medicine and aerospace fields.

Q: How does the flyeye lens lens achieve uniform light? What advantages does it have?

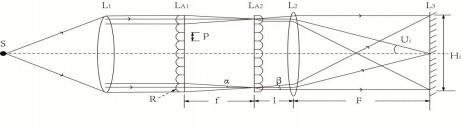

Answer: the flyeye lens lens array achieve uniform lighting principle is: parallel to the optical axis through the first lens after focusing in the center of the second lens, the first row of flyeye lens lens crosslight source form multiple light like for illumination, the second row of flyeye lens lens each small lens will be the first row of flyeye lens lens corresponding small lens overlap imaging on the illumination surface. Because the first row of flyeye lens lens divides the entire wide beam of the light source into multiple thin beam illumination, and the vertical axis inhomogeneity within the range of each thin beam, the superposition of thin beams in a symmetrical position, the vertical axis inhomogeneity of the thin beam is compensated, so that the light energy in the entire aperture is effectively and uniformly utilized. The light spot emitted from the second row of the flyeye lens lens is focused on the illumination screen through the condenser. In this way, every point of the spot on the lighting screen is illuminated by the light emitted from all the points of the light source.At the same time, the beam from each point on the light source will overlap within the same field of view on the illuminated spot, giving a uniform spot.

Simple diagram of light source:

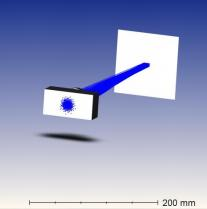

Optical design effect drawing:

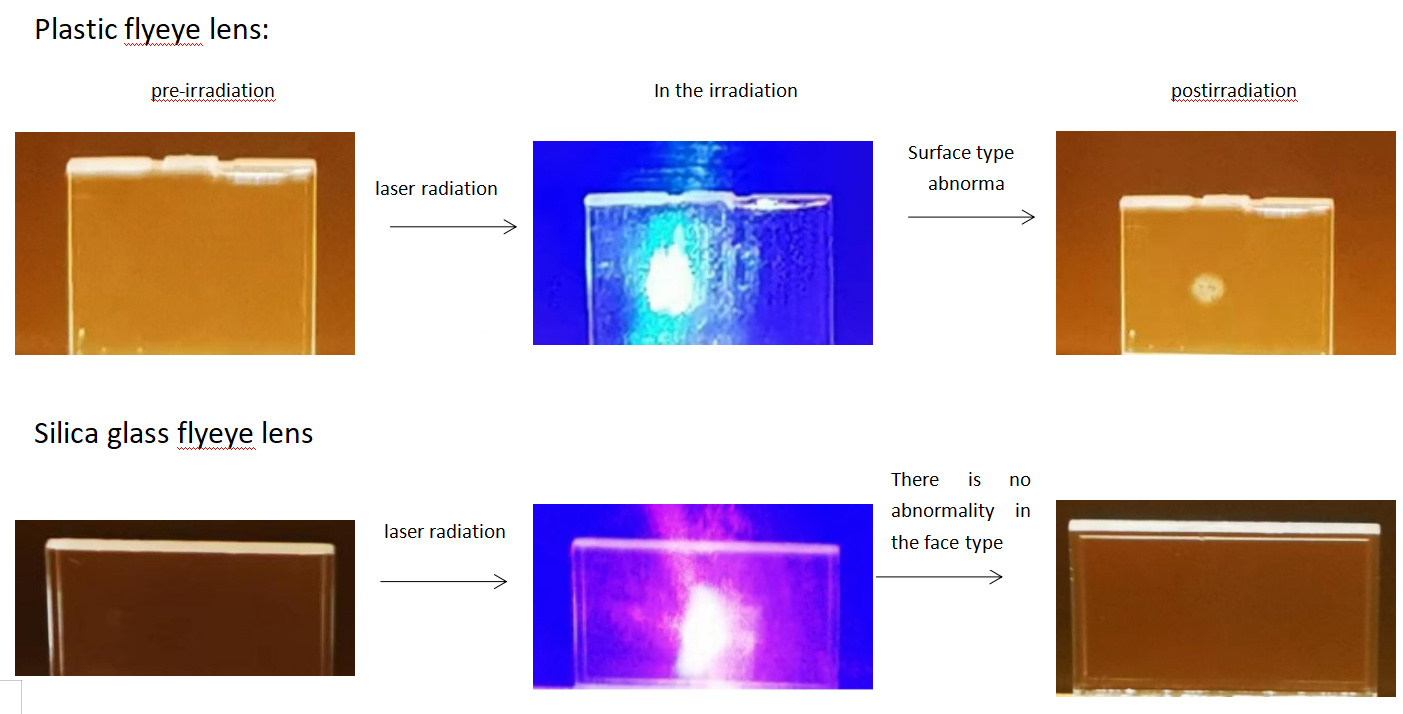

Usually the common flyeye lens on the market is generally divided into two kinds: Silica glass flyeye lens and Plastic flyeye lens. Silica glass flyeye lens has more advantages because of its high temperature resistance, corrosion resistance, good thermal stability, good light transmittance and other characteristics, compared with Plastic flyeye lens, often used in exposure machine, micro-display and high-end home appliances and other fields. According to the market research, the use of Silica glass flyeye lens in the market showed a 20% annual growth trend.

The difference between Silica glass flyeye lens and Plastic flyeye lens:

|

Project |

Silica glass flyeye lens |

Plastic flyeye lens |

|

Material quality |

Silica |

Plastic |

|

Melting temperature |

1000℃ |

130℃ |

|

Transmissivity |

More than 93% |

85%-93% |

|

Operating cycles |

10-15 Years |

1-2 Years |

|

Stability |

Strong stability |

Instability |

Comparison between Silica glass flyeye lens and Plastic flyeye lens after laser irradiation:

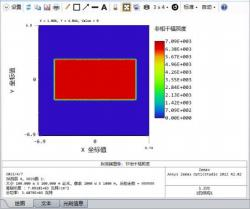

Q: How to distinguish between the quality of the flyeye lens? What equipment can be distinguished from it?

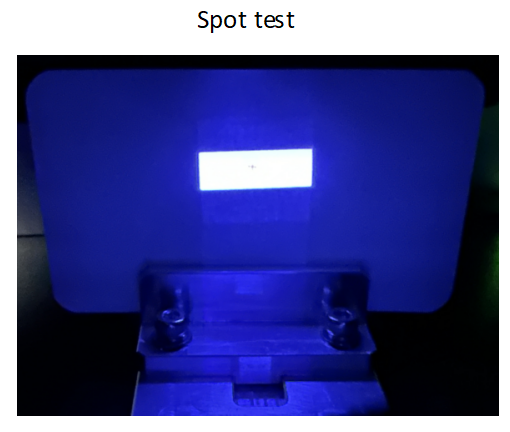

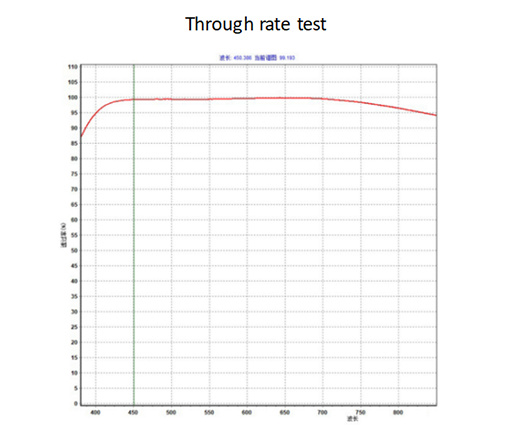

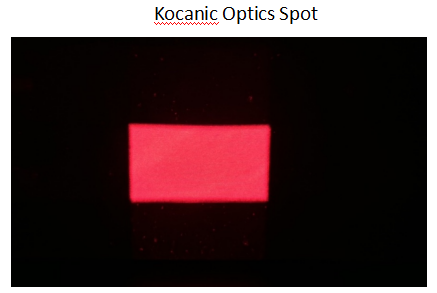

A: In addition to the traditional test methods, you can also choose high-tech, accurate test methods. We have added a spot test machine and a transmittance tester, and the spot test machine can be judged by the size, shape, and sharpness of the spot hit. Generally speaking, the four sides of the normal light spots are more sharp, the concentrating effect is better, the abnormal light spots are more smooth, the four sides of the light spot will be scattered around, the concentrating effect is very poor. The transmittance tester can identify whether the material can achieve the transmittance and the stability of the coating band through the curve shown by the transmittance test.

Examples of light spots:

With the rapid development of optical technology, many optical technologies have been widely used. Silica glass flyeye lens lens, as a rising star of optical lens, has been recognized by the market after more than 10 years of development. In the application of laser, it presents a growing trend every year. I believe that in the future development will be getting better and better!

Previous Page

Next Page

Recommended Articles

透镜,让世界更美好

2 minutes to understand the principle of the microstructure array lens

Microstructure array lenses are formed by nanoscale sub-lenses arranged in a certain order. Since each sublens in the microstructure array lens has an independent optical axis, a main optical axis is formed. Therefore, compared with the traditional compound eye single lens, the microstructure array lens has extremely high parallelism, and each sub-lens can transmit the light source independently of each other without interfering with each other.

What do you know about a spherical lens?

A spherical lens is a lens with a fixed radius of curvature on the surface of the lens inside the optical aperture. Spherical lenses are mainly divided into double convex lens, flat and concave lens, concave and convex lens, double concave lens, etc., which can be customized according to customer drawings or sample processing, to meet the different application needs of customers.

The difference between the Powell prism and the cylindrical array mirror

Powell prism: It is an optical nonspherical cylindrical mirror that allows the laser beam to preferably form a straight line with uniform density. Cylinder array mirror: Cylinder array mirror belongs to a kind of lens array. The core is the cylindrical microstructure distributed above, which can effectively reduce the spherical difference and chromatic difference by designing the aspherical surface shape, and has a one-dimensional amplification function.