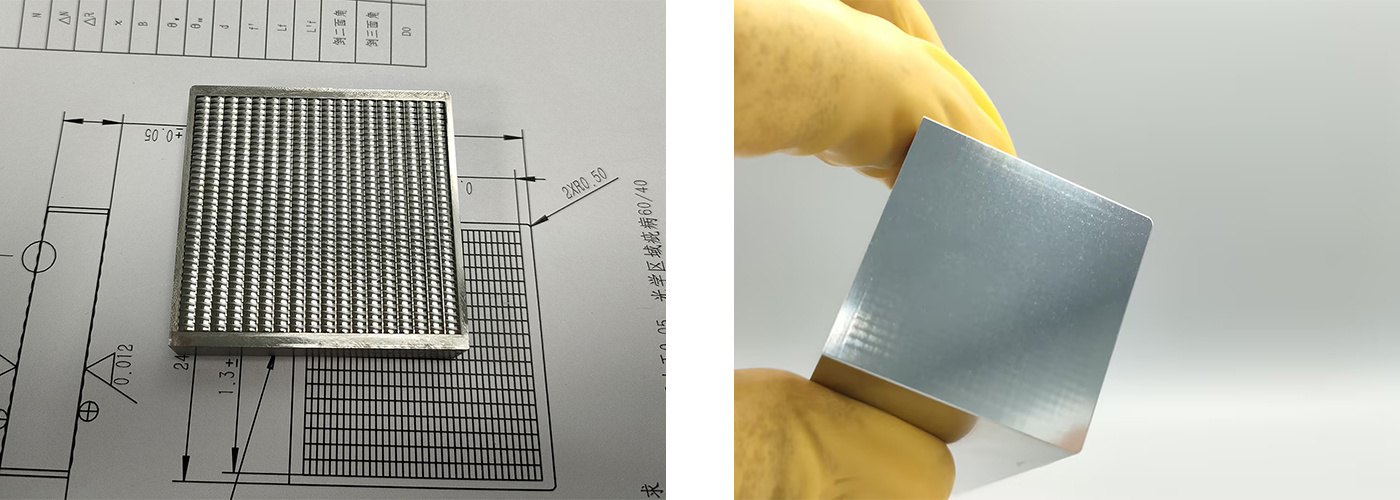

Mold display

Introduction of 1. mould

Optical mold is a key tool for manufacturing optical components, and its quality and accuracy directly affect the performance of optical components. Our mold design team has many years of professional experience and can manufacture high-quality, high-precision optical molds to meet various application requirements.

2. mold material

Aode Optoelectronics uses the most advanced mold materials to ensure high precision and long life. The main materials include high-grade steel, hard alloy, ceramics, etc. These materials have the characteristics of high hardness, high wear resistance, high corrosion resistance, etc., which can ensure the stable performance of the mold during long-term use.

3. manufacturing process

The manufacturing process of Aode Optoelectronics adopts advanced ultra-precision machining technology, including grinding, polishing, and EDM. These technologies can achieve micro-scale or even nano-scale processing accuracy to ensure the surface quality and geometric accuracy of the mold. At the same time, we also use special heat treatment and surface treatment processes to improve the hardness and durability of the mold.

4. mold type

Aode Optoelectronics has a complete range of molds, including compound eye molds, microstructure molds, cylindrical lens molds, spherical lens molds, and aspheric lens molds. These molds can be used to manufacture a variety of different types of optical components, such as fly-eye lenses, micro-structure lenses, cylindrical lenses, spherical lenses, aspherical lenses, etc. We can also customize special types of molds according to customer needs to meet different application needs.

5. Quality Assurance

Aode Optoelectronics strictly abides by the quality management system to ensure that every mold has undergone strict testing and testing. We use high-precision measuring equipment to comprehensively test the size, shape and surface quality of the mold to ensure that it meets the design requirements and customer standards. At the same time, we also conduct life testing and performance verification to ensure that the mold has reliable performance and long life during use.

6. epilogue

Optical molds of Aode Optoelectronics are known for their high quality, high precision and high reliability, and are widely used in the manufacture of various optical components. We believe that with excellent quality and professional service, our optical mold will win more customers' trust and support.